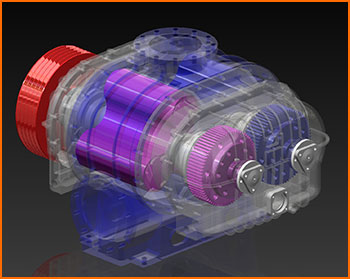

Three Lobe Rotary Blowers

AMCL in collaboration with world leaders Unozawa-Gumi Iron works Ltd. of Japan, brings to India advanced technology to manufacture the most rugged and efficient industrial blowers. AMCL's Tri-Lobe design, positive displacement blowers work in the most exacting conditions with least vibration and noise ensuring constant volume discharge of oil free air/gas with high efficiency.

Advantages

- Low pressure pulsation

- Less noise & vibration

- High volumetric efficiency

- Low discharge temperature

- Low power consumption

- 100% oil free air/gas

- Low maintenance and low spares inventory

Application

- Cement Industry

- Sugar Industry

- Fertilizer Plants

- Chemical Plants

- Iron & Steel Plant

- Textile & Paper Mill

- Water Effluent treatment Plants

The AMCL- Three Lobe Positive Displacement Blower (Root type) have been developed under Technical Collaboration with world leader UNOZAWA Gumi Iron Works Ltd. Japan, incorporating AMCL’s extensive experience and technical expertise. These ARJ Series high performance Blowers employ three lobe rotor designs which reduce noise and vibration level. This World Class mechanical marvel is indigenously manufactured at AMCL’s state –of-the-art plant at Butibori near Nagpur. These Blowers are working in different industries in India and abroad at utmost satisfaction of our customers due to excellent product performance and our after sales parts and service support.

Notes :-

- Qs-Free Air Delivery (FAD) in m3/min

- Air volume listed in the Rotary Blower performance tables represent the standard suction state (Temperature 35° Absolute pressure 10332 mmWG-101.3 KPa, Relative Humidity 65%). The suction pressure is atmospheric for the rotary blower and vacuum pressure for the rotary vacuum pump.

- Between two adjacent blower models, air volumes at boundary level overlap. Either of the two models can be used, but from an economic standpoint it is recommended that the smaller model be used.Occasionally, however, the larger model is used at low speed in consideration of noise levels.

- Shaft horse power listed in the performance tables is the requirement for transmission (v-belt). A motor with an output corresponding to the listed shaft horse power can be used. However, it will be better to use a motor whose output is 10-20 % larger than the shaft horse power. The use of an excessively larger motor would result in unnecessary energy waste, due to increase in no-load current causing motor efficiency to drop..

- For your requirement of blowers other than capacities mentioned above, please write to us.

- In view of continuous product development the specifications are subject to change without prior notice.

AMCL Three Lobe Positive Displacement Blowers

AMCL - UNOZAWA Three Lobe Positive Displacement Blowers |

|

Features |

Benefits |

Three lobe rotor design

|

Leads to lower range of pressure pulsations at discharge. Results in smoother air discharge Low levels of noise < 90-100 dbA, vibration less than 80 Microns Lower shock loading of bearings and timing gears |

Heat-treated castings of graded cast irons |

Improves grain structure and ensures dimensional stability, results in higher reliability and lower maintenance |

Dynamically balanced rotors

|

Lower to noise, vibration levels and reduced bearing loads. Results in smoother operation, low maintenance, higher reliability. |

Alloy steel hardened, ground |

Leads to lower gear running noise, low wear & longer life of gears. |

High quality, amply designed anti-friction bearings |

Long life of bearings- virtually maintenance free and smooth operation. |

Intermediate chamber side covers |

Prevent oil leakage into main chamber and ensure 100% oil free air |

Optimum internal clearances |

Reduce air slippage giving high volumetric and energy efficiency and lower air discharge temperature (generally less than 100 Deg C.) |

Bottom Horizontal discharge design with lube oil cooling facility. |

Compact installation, maintains low lube oil temperature which minimizes wear of gears and bearings. |

Engineered, high quality accessories |

Reliable, trouble free operation with guaranteed performance. |

Our Clients