Mixtron BB Series Mixers

Resulting from its on-going endeavor to produce high-tech products, AMCL in collaboration with World leader Kobe Steel Ltd., of Japan, brings to India advanced technology to manufacture the most rugged and efficient internal mixers for the rubber industry at its modern manufacturing plant at Butibori, near Nagpur. Backed by the latest machinery laid out in a covered area of 5000 Sq. m, the Company's highly trained and experienced personnel practice its Corporate philosophy which gives importance to customer satisfaction through value-added products and services.

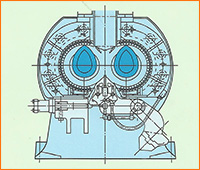

Mixtron BB Series mixers are highly versatile range of batch mixers for the rubber industry. Backed by the international technology of Banbury Mixers, which Kobe Steel Ltd., produced under license for many years, the new Mixtron BB Series are outcome of over four decades of research, development and innovation.

Mixtron BB Series Mixer's Features

- High productivity

- Consistent and uniform mixing

- Minimum energy input

- Least maintenance.

Mixtron BB Series mixers incorporates many • exclusive features which are internationally patented by Kobe Steel Ltd., such as :

- 4 Wing H Rotor

- Mechanically Driven Ramming System

- Even - Speed Mixing System

- Optimum – Orientation

Mixtron BB Rotor

Rotor is the heart of the Mixtron BB mixers. Intensive research and development have gone into the design of this critical component to ensure superior batch mixing. AMCL offers Rotor designs for each mixer model based on the material and conditions of mixing. 2WS Rotors are normally fitted in BB 76 mixers 4 wing H Rotors are for BB 270 mixers.

2 WS Rotors

- The two - wing type of rotors are particularly effective for a wide range of rubbers.

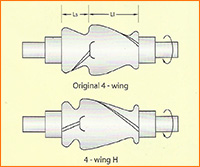

4 wing H Rotors (Patented)

- The 4 wing H - rotors are designed and developed for large-batch mix productivity with minimum energy consumption.

- The 4 WH swirl rotors provide excellent dispersion in the mix, generates smooth material circulation within the chamber, and maintains an even temperature and pressure throughout the mix.

High - Speed Mixing System

High quality and productivity of one or more size upper class conventional rotors can be accomplished by combining the optimal chip clearance and rotating speed based on technologies of 4 WH rotors

Relation between Wing Lenght / Dispersion

Mixtron BB Mixer - Range

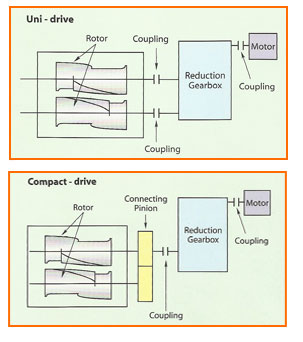

The Mixtron BB mixers are available in two sizes BB 76 and BB 270. Compact drive system is generally given to BB 76 mixers while BB 270 mixers are with Uni - drive system. These mixers are provided with high power mixing mode to handle tough rubbers. Nominal batch capacity is influenced by Fill factor and Specific gravity of the rubber and is arrived at by Batch Capacity = Net Chamber Volume x Fill Factor x Specific Gravity. The fill factor varies between 0.68 and 0.9 and is dependent on the viscosity of the material being mixed, the rotor type, its speed and the ramming pressure.

Technical Data

| Specification / Model | BB-76 | BB-270 | ||

| Net chamber volume (Lts.) | 2WS Rotor | 76 | 270 | |

| 4WH Rotor | 68 | 255 | ||

| Nominal batch |

Capacity ( kg ) | 2WS Rotor | 65 | 220 |

| ( Specific gravity 1.0 ) | 4WH Rotor | 51 | 191 | |

Normal mixing

|

||||

| 37 | 60 | |||

| 150 | 1200 | |||

High-Power mixing

|

||||

| 37 | 60 | |||

| 190 | 1500 | |||

Approximate Dimension

|

||||

| 5.6 | 8.1 | |||

| 2.7 | 3.8 | |||

| 3.8 | 6.1 | |||

| Approximate Weight ( Tons ) | 13.0 | 55 | ||

| Approximate Cooling water consupmtion ( lt/min. ) | 400 | 1000 | ||

Product Features

Cost - effective Batch Mix Four decades of KOBE STEEL's experience and customer feedback have facilitated continuous development and refinement of Mixtron BB range. As a result, the batch mixer uses very little process/lubrication oil and minimum air supply making the batch mix cost - effective.

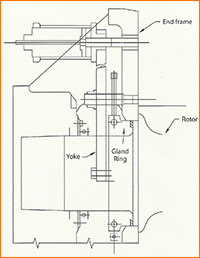

Rotor Seals The rotor seals of the Mixtron BB range are ideally designed not only for preventing dust leakage but also for durability and minimum use of process/lubrication oil.

YH Dust-Stop Seals All models are fitted with hydraulically loaded yoke against the rotor, ensuring fool - proof sealing. The design is simple and functional, needs no adjustment and is durable to give long service.

Discharge door :

A drop door beneath the mixing chamber facilitates rapid unloading of the mixed batches to minimize the cycle time. The leak proof door is self - aligning to the underside of the mixing chamber ensuring perfect sealing. The internal face of the discharge door can be easily replaced on being worn out due to mixing action.

Our Clients