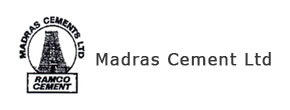

Vertical Roller Mill

Introduction

The Vertical Roller Mills developed by AMCL Machinery Limited are based on technical knowhow from Nihon Cement Co. Ltd. Japan. These machines are used for substantial power saving and capacity enhancement in the field of Clinker and Rawmeal Grinding. We have over two decades of experience in supply and installations of Vertical Pre Grinding. We have supplied 30 Installations in India & Middle East.

Principle of Operation

Clinker or Limestone is fed through a central chute in the VRM where centrifugal force, combined with the rotation of the table, distributes product over the table surface. The table and rollers then grind the material, which is then extracted from the VRM by gravity and a little help from a scrapper. A grinding force is transmitted to a set of three rollers at 120 Degree apart through a hydraulic system.

We are offering our Mill System for up gradation and optimization of existing Cement plants and Raw Grinding Systems

The VRM can be used in

- Pre Grinding Mode

- Hybrid Mode

- Finish Mode

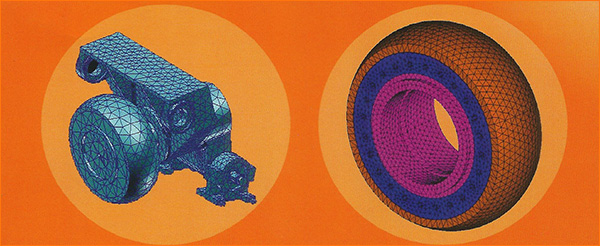

Constructional Feature

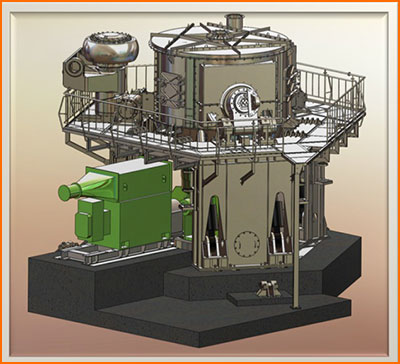

Rollers:

Roller type is made from special alloy steel castings and are confirming to Nihon Cement Specification AT-C for wear resistance. Spherical shape of roller increases its life. Roller Shaft made out of special alloy steel duly hardened tempered and ground. Roller shafts are clamped to the journal head which are hinged to the spindle. Grinding Force is provided by hydraulic cylinder transmitted to Roller Through Spindle

Grinding Table:

The grinding table made out of high grade cast steel is directly mounted on gear box output Flange. The upper surface of the table is fitted with table liner segments constructed of special wear resistant cast steel and held in place with retainer ring. The table liner is divided into segments for ease of handling. A scrapping paddle is indatlled below the table and the paddle is driven by rotation of the table.

In-house Design, Development and Analysis Facility

Typical Particle Size Distribution*

Size |

VRM Feed(%) |

VRM Outlet(%) |

Product From Screen |

(+) 25 mm |

5.4 |

|

|

(+) 12.5 mm |

35.5 |

0.8 |

|

(+) 6.3 mm |

67.6 |

10.7 |

|

(+) 3 mm |

88.4 |

27.5 |

7.4 |

(+) 1 mm |

98 |

32.7 |

25.6 |

(+) 212 Micron |

|

54.9 |

50.7 |

(+) 90 Micron |

|

67.6 |

65 |

(+) 45 Micron |

|

81.5 |

76.2 |

(-) 45 Micron |

|

18.5 |

23.8 |

VRM Series Technical Data

| Model | VRM 180 - 3 | VRM 230 - 3 | VRM 270 - 3 |

| Capacity (TPH) | 90-120 | 150-170 | 210-250 |

| Table dia. (mm) | 1800 | 2300 | 2700 |

| Motor (Kw) | 750 | 1200 | 1850 |

| Weight (Tons) | 100 | 160 | 260 |

VRM Series – Technical Specification

We Supply world Renowned Make Planetary Gearbox suitable for VRM models based on the motor kw.

First stage : Bevel gear

Second Stage : Planetary Gear

Advantages of Using a VRM

- Non- air swept grinding and is therefore energy sufficient

- Approx. 50% - 70% increase in Grinding Capacity

- Low Maintenance

- Specific Power Consumption of Grinding System can be reduced by 15 – 20 %

- Long Life for table liner and roller.

Salient Features of the VRM

High Efficiency spherical roller grinding mechanism

The centrifugal force generated by the rotation of the table spreads the material across the entire table surface in a uniform layer, where it is caught between the roller and the table liner segments and crushed before being carried to the outer circumference of the table. The grinding Force is transmitted by Roller at the same time through a Hydraulic system. Spherical Rollers also offer high compressive force between table and roller which generates greater shearing force. Therefore high efficiency grinding is carried out by simultaneous compression and shearing force

Uniform grinding

As spherical rollers have higher periphery, a wider uniform grinding layer is formed and hence increases grinding efficiency.

Fluctuation in quality and quality if clinker

Fluctuations is clinker size and feed rate can easily be accommodated.

Possible Configurations

Several Configurations are possible, such an as open circuit mill, close circuit mill and feeding to more than one ball mill.

Compactness

VRM is very compact hence require little space. It can be accommodated easily in existing plants.

Chemical Composition and Mechanical Properties of Chromium Cast Steel Used

Symbol |

Chemical Composition |

Hardness(Hs) |

Impact Value(Kg-m/CM2) |

Tensile Strength |

Application |

||

|

C |

Cr |

|

|

|

|

|

Grade – C |

3.0 |

20.0 |

Mo, Ni |

>90 |

>0.5 |

>70 |

Extra Heavy Wear – resistant materials etc |

Grade – M |

3.0 |

20.0 |

Mo,Ni |

>85 |

>0.5 |

>70 |

Heavy Wear – resistant Material, etc |

Grade – F |

3.0 |

15.0 |

Mo |

>90 |

>0.5 |

>70 |

High Grade wear- resistant material etc |

Advantages of (VRM) System for Clinker

Capacity Increase: 50 to 100 %

The very compressive force on clinker lumps between rollers and table causes numerous hair line cracks to form, resulting in easy clinker grinding in tube mills.

Power saving: 15 to more than 25 %

As clinker is made easier to grind, power consumption in the tube mills is reduced. Input electric power works as direct energy, crushing clinker lumps efficiently between rollers and table instead of as potential energy through balls in a conventional tube mill; this also results in reduced ball size in tube mill and reduced noise emission.

Long life of consumable parts (20,000 hrs. for Roller Liner, 10,000 hrs. for Table Liner)

AMCL's own machined high chromium cast steel which has been subjected to special heat treatments, has tremendous durability, even against highly abrasive materials such as clinker and blast furnace slag to "An ideal solution for optimizing an existing Ball Mill as well as for new installation."

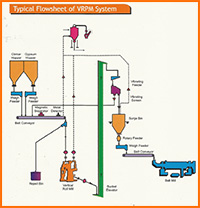

Description of VRM Cement

VRM works in a closed circuit with Multi Deck Screen, Clinker and Gypsum are fed to the feed of chute of VRM. The output of VRM is fed into Multi-Deck Screen through Bucket elevator from where + 3mm size is re-circulated to VRM and – 3 mm size is re-circulated to the Ball Mill. These – 3mm size contains considerable amount of fines. The output Ball Mill goes to the cement silo through Separator and Bucket elevator.

Our Clients